Xbar-S Charts can be created in Microsoft Excel or in Minitab. This is because the constants used in the equations change with changing subgroup sample size. When the subgroup sizes are not equal, the control limit lines will not be straight lines but rather will be stair-stepped.

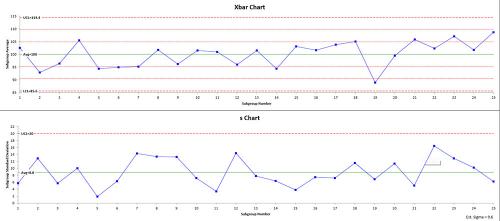

However, they should always be greater than 10 data points. One other advantage of the Xbar-S chart is that it can work with subgroup sizes that vary slightly. The standard deviation is always a positive number. The Standard Deviation chart plots the value of the standard deviation for all the subgroups. The Subgroup Mean chart plots the average value of the data points that were used to sample the subgroup. This aids in the recognition of special cause occurrences. These are normally aligned so that the Subgroup Mean (Xbar) chart is directly above the Standard Deviation chart. The Xbar-S is comprised of a pair of control charts.

The standard deviation uses all the data points and is not as easily impacted by an outlier. With high volume and a large number of data points, the standard deviation is a better gauge of the subgroup variation than is the range from max value to min value. Use the Xbar-S Chart when seeking to control a product or process variable parameter with a high volume process. It can be easily created in either Microsoft Excel or Minitab. The Xbar-S chart (Subgroup Mean and Standard Deviation) are the variable data control chart to be used when working with a subgroup sample that has ten or more units.

0 kommentar(er)

0 kommentar(er)